DEWATERING SOLUTIONS WITH RUNI!

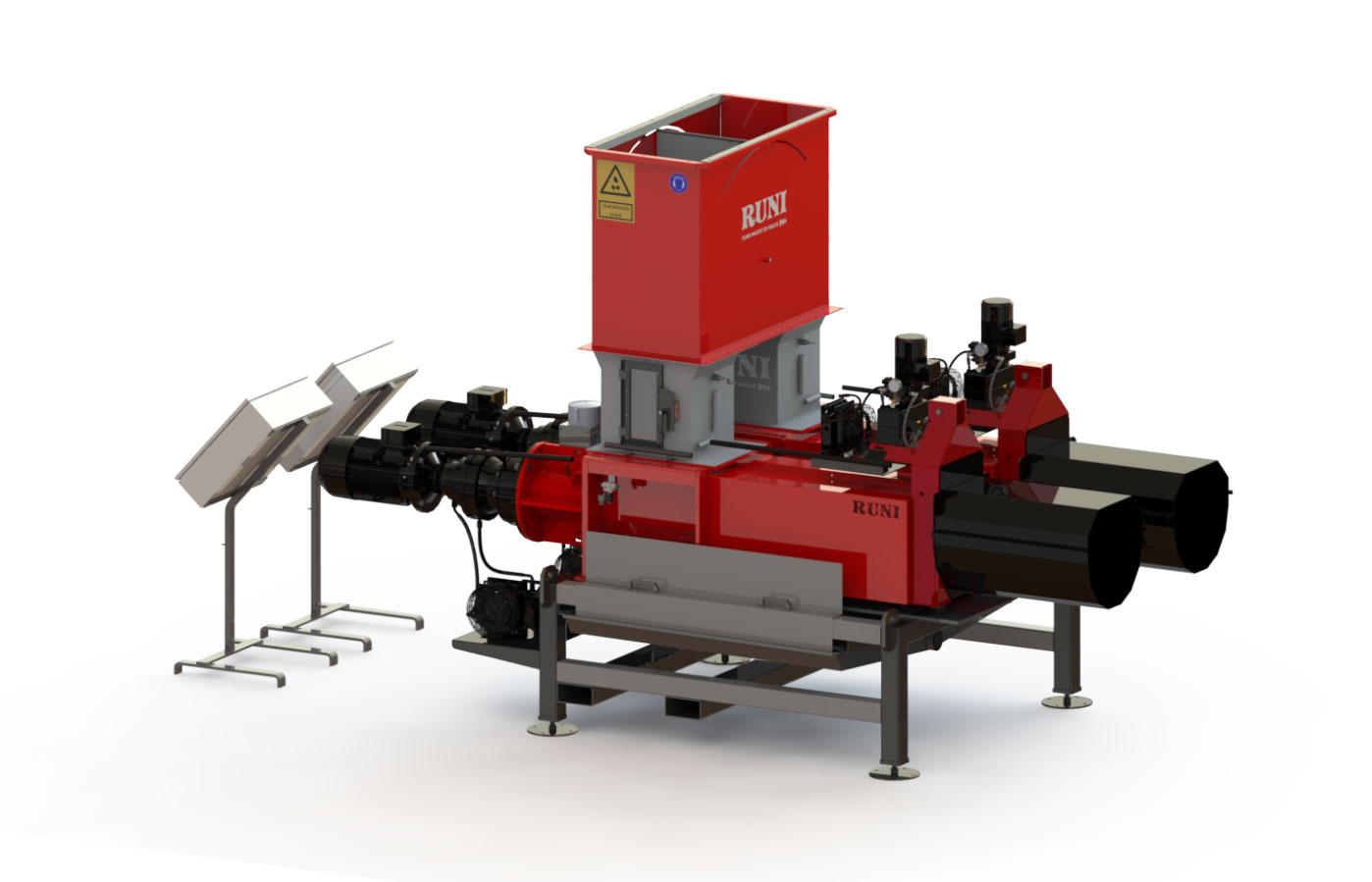

The SK370 Screw Compactor is a large, heavy-duty, versatile machine that compresses a wide variety of different materials, including challenging tasks that other machines struggle with. Purpose-built recycling machines.

Runi Screw Compactors consist of a fundamental unit available in three dimensions and used in all machines. Additionally, there are standard or customized accessories that make the machine particularly suitable for the specific task it will perform.

The primary goal is always to customize the compactor to fit the customer's existing production facility as closely as possible. At the core of the machine, there is a hydraulic-automatic feeding control system that ensures even compression for all materials, without overloading the compactor.

The RUNI SK370 can be equipped with a wide range of accessories, including various feeding bunkers for manual or automatic feeding, conveyor belts, silo systems, a drainage matrix for water drainage and separation, and more

Dewatering RDF/SRF Waste

RDF/SRF (Refuse-Derived Fuel/Solid Recovered Fuel) refers to waste materials used as fuel in waste-to-energy plants or cement kilns. Dewatering may be necessary to optimize the fuel value. The RUNI screw compactor can continuously dewater RDF/SRF with low energy consumption.

Conditions in RDF facilities are highly challenging, and these facilities operate 24/7 throughout the year. RDF often contains abrasive elements like sand. Therefore, there are high expectations from the machine, and RUNI can meet those expectations.

RUNI Screw Compactor Solution for RDF/SRF Waste

The RUNI SK370 screw compactor is a robust and reliable machine built with reinforced screws and a capacity of 4-5 tons per hour, designed to work 24/7. It has proven its efficiency over the years. The screw compactor can be installed as the final element in the processing line and can be directly fed with a conveyor belt.

The benefits of the SK370 model:

Bigger screw, more power, higher capacity: The SK370 features a larger screw design, providing more power and the ability to handle higher capacities of waste.

Profit from converting waste into reusable materials: The SK370 allows for the compression and dewatering of waste, resulting in the generation of reusable materials. This reduces costs and enables revenue generation from waste management.

Save space and transportation costs by processing waste quickly and efficiently: The SK370 efficiently compresses and dewateres waste, reducing its volume. This saves storage space and lowers transportation costs.

Energy-saving - no heat required during the process: The SK370 achieves energy savings as it does not require heat during the process. This helps reduce energy costs.

Different configurations for various materials: The SK370 offers different configurations to handle a wide range of materials.

Reduce manual labor: The SK370 minimizes the need for manual labor in waste processing.

Safe and easy operation with automatic start and stop functions.

Other products that RUNI screw compactors can separate and dry include:

- Separation and drying with RUNI:

- Paper (Pulper waste)

- Plastic washing plant rejects

- RDF (Automobile Shredder Residue)

- PET bottles

- Wet beverage can labels

- Aluminum and tin cans

- LDPE (Low-Density Polyethylene)

- Fruits and vegetables

- Packaged milk and dairy products

- Packaged cosmetic products

- Plastic drums up to 30 liters

- Paint cans

- Beverage cans

- Dewatering of food waste for biogas plants.

- MateryalRDF

- Achieved dry matter percent 75%

- Capacity per hour 5-10 tonnes

- Daily capacity 120-240 tonnes

- Feed opening dimension(standard) 600x420 mm

- Weight 1500 kg

- Machine dimension (LxBxH) (standard) 4358x1444x2120

- Motor Power

- Main Motor 15 kW

- Hydraulic pump 0,55 kW

- Oil cooling for gear 0,07 kW

- Oil cooling for hydraulic 0,07 kW

- Circulation pump 0,25 kW

- Power Supply 3x400V, 50 hz, 63A

- Marking CE Approved