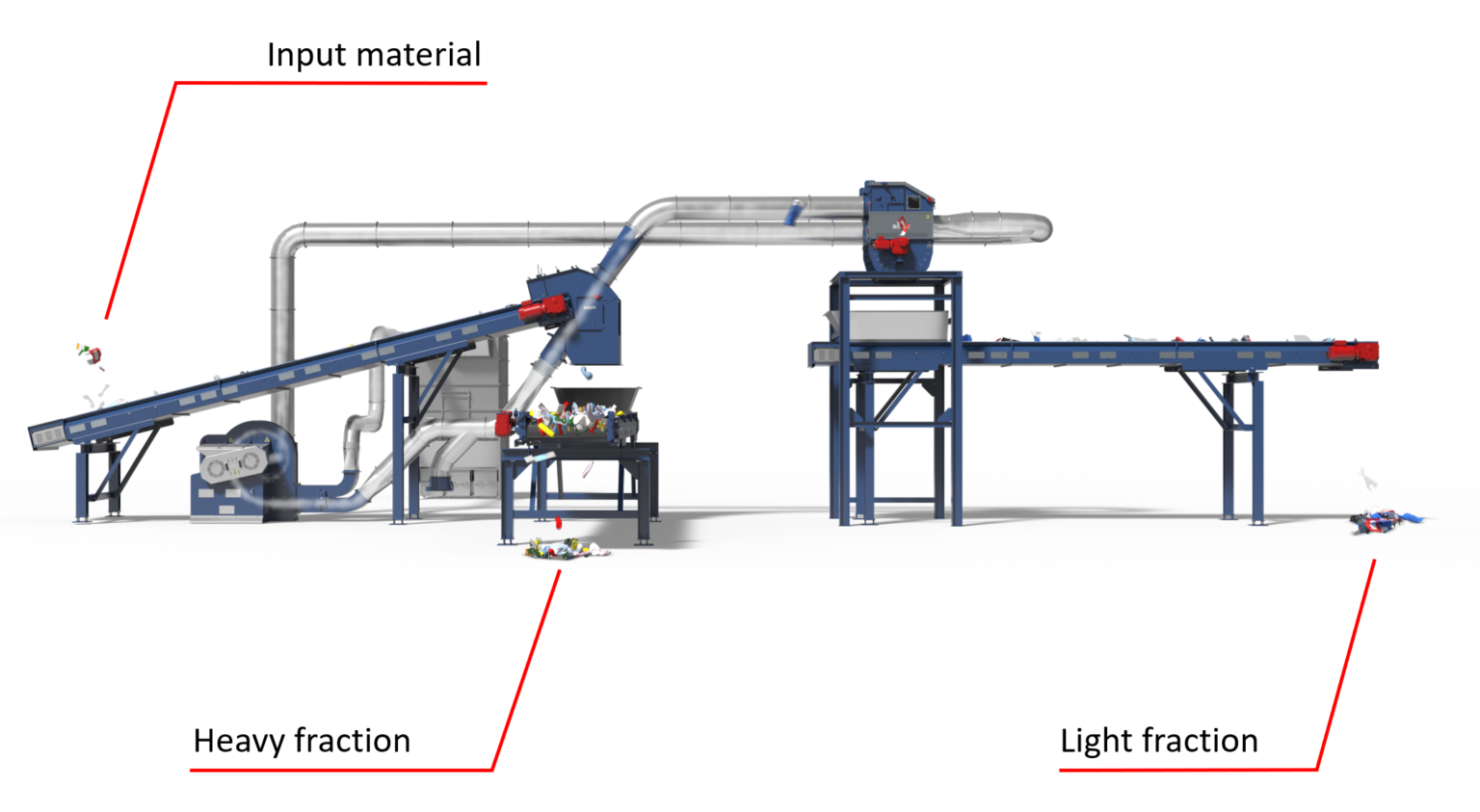

WSF windshifter

The Nihot WSF windshifters is the ideal solution for light packaging waste applications where only plastic film and foils need to be recovered we offer and supply our dedicated WSF windshifter. Our WSF windshifter and Rotary Air Separator (RAS) combination is the ideal solution for capturing plastic film in tight spaces and can be installed into different locations within the waste installation. It’s a great option for any system, but the flexible footprint also makes it a great candidate for retrofits.

The typical characteristic of a diagonal windshifter is the use of a blow nozzle. About 60% of the aspirated air is returned back into the system. This allows for a smaller dust filter. But more over it helps to control the separation efficiency since we can fully adjust the blown air separately from the aspirated air. The WSF windshifter offers high separation efficiency with flexible footprint and can process fraction sizes of 20-400 mm and is mainly used in light packaging waste (DSD/PMD), PET, MSW and compost. Material is pneumatically conveyed, creating a great deal of flexibility for conveyor placement and duct routing.

Advantages

• High separation efficiency of up to 99%

• Flexible, can be set up in many different ways/layouts

• Adjustable separation settings during operation provide superior separation efficiency

• Up to 60% of the exhaust air is re-used and this allows for a smaller dust filter

• Versatility to process a wide variety of waste streams, especially light packaging material

• Low energy consumption due to our unique configuration with a recirculation fan

• Low maintenance and very few wearable parts, i.e. reduced downtime, low operational costs

• Dust free operation – positive effect of negative pressure technology